Fabric Expansion Joints | GfG-Kompensatoren mbH

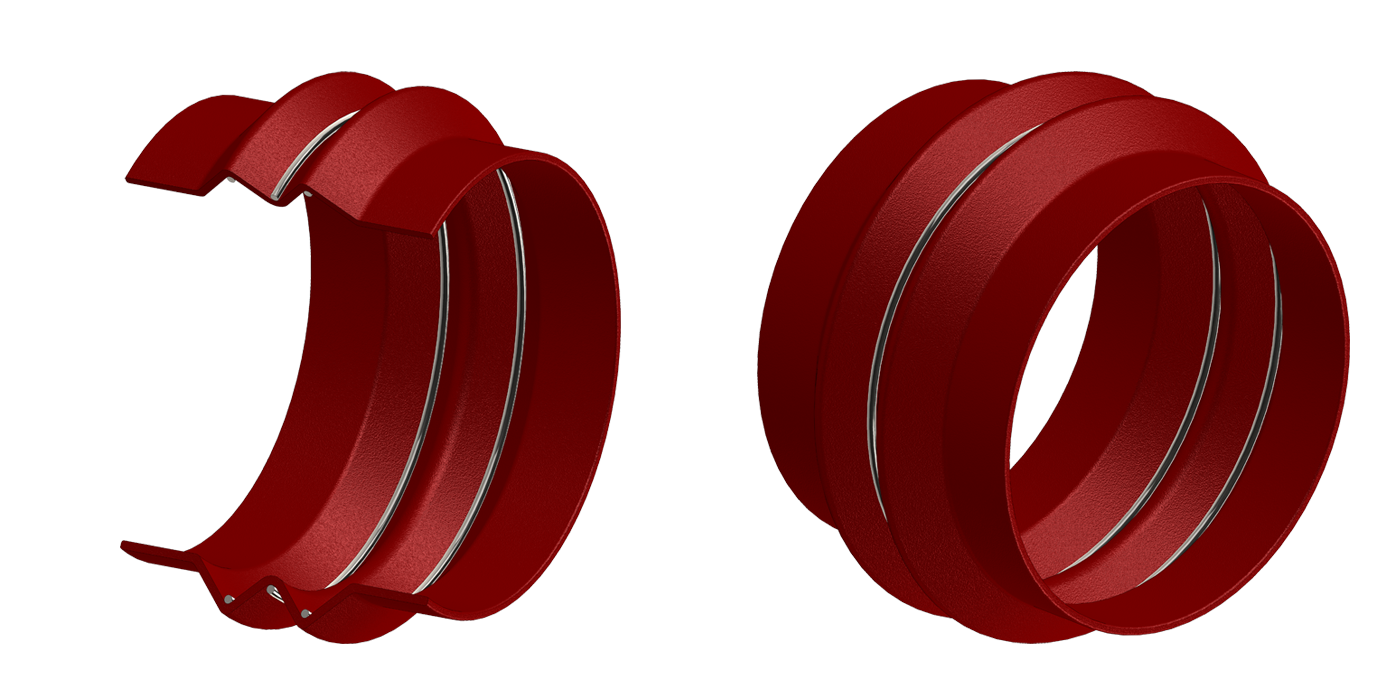

An expansion joint is a flexible element that compensates movements between pipelines, among other things in case of vibrations in lateral or axial directions, temperature differences, or wall ducts. They are used in pipeline construction as well as in plant and apparatus construction. Depending on the application, expansion joints are made of different materials. Neoprene, EPDM, Hypalon, silicone, Viton, or PTFE are used among other materials.

Designs

For our customers, we manufacture each expansion joint individually.

In the process, we take into account the respective operation-specific parameters.

Substantially, three designs can be distinguished:

Tube expansion joint I

Mounting directly on the pipeline

Dimensions

Media temperature

Pressure

Expansion absorption

Tube expansion joint II

Mounting on pulled out mounting flanges

Dimensions

Media temperature

Pressure

Expansion absorption

Flange expansion joint

With self-sealing flanges and single or multi-part backing flanges

Dimensions

Media temperature

Pressure

Expansion absorption

Groups of material

By using various materials and respective material combinations, it is possible to work out an optimal problem solution both from a technical and economic point of view. This is substantially determined by the

mechanical

chemical and

thermal

influences.

The design itself is always defined by the following groups of material and the corresponding tasks:

Insulating material

Sealing foil

Backing fabric

Coating

Do you have any questions? We are gladly at your disposal.

GfG-Kompensatoren mbH

Zum Steingraben 9

95503 Hummeltal

Upper Franconia / Bavaria

Links

to the whole world